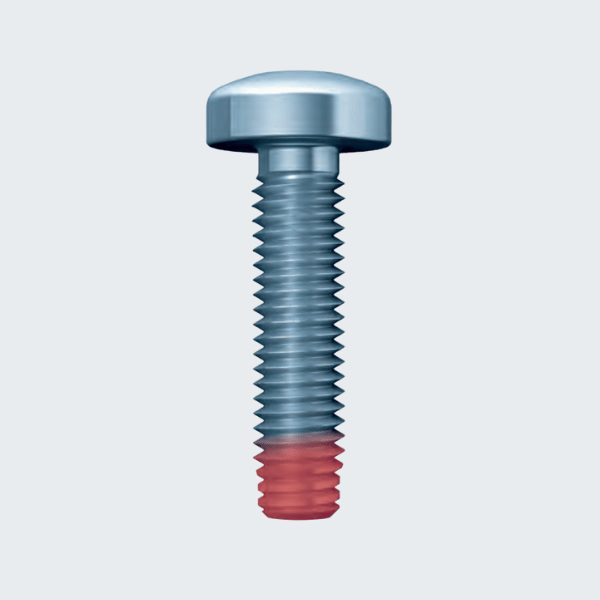

MAXXtip®

Gängformande för (ultra) höghållfast stål och gjutjärn

- Processäker direktmontering i Ultrahöghållfasta stål

- Processäker direktmontering i Gjutjärn

- Helt okänslig för väteförsprödning, även med galvaniska beläggningar.

- Löstagbar led.

EJOT MAXXtip® kombinerar ett karbohärdat skaft med en ultrahård skruvspets. Den här unika kombinationen ger helt nya möjligheter till direkt infästning i (ultra)höghållfasta material.

På grund av den karbohärdade mikrostrukturen (hållfasthet motsvarande 10,9) i det lastbärande området är MAXXtip®-skruvarna okänsliga för väteförsprödning. Därför kan galvaniska ytor appliceras utan anlöpning, vilket leder till en hårdhet på gängflanken på minst 750 HV* i formningsområdet.

*När det gäller ytor med Zn-flakes, leder värmebehandling till en reducerad gängsflankshårdhet i formningsområdet på minst 600 HV.

Applikationer för EJOT MAXXtip®

- För (Ultra) höghållfasta stålplåtar (minst UTS på 1200 MPa)

- SHEETtracs® upp till 2 mm

- Spiralform® motsvarande DIN 7500

- Gjutjärn (GJS och GJL) med Spiralform®-gänga

Vill du veta mer? Kontakta våra experter!

Gunnar Nygren

+46 (0)703 700 105

gnygren@ejot.com

+46 (0)703 700 105

gnygren@ejot.com

Niclas Jonsson

+46 (0)703 700 146

njonsson@ejot.com

+46 (0)703 700 146

njonsson@ejot.com

Kundtjänst

+46 (0)19 20 65 10

infoSE@ejot.com

+46 (0)19 20 65 10

infoSE@ejot.com